Rebar might be a standard steel bar or block which is widely applied in reinforced concrete and bolstered masonry buildings. These rebars usually are produced from carbon metal which enable it to be recounted as reinforcing metal or perhaps reinforcement. Below Structural BIM Providers Rebar detailing is usually a self-discipline of creating fabrication or shop drawings of metal reinforcement to your development approach. The website fabrication drawings that may be created determined by design and style drawings for reinforcing steel are Rebar Specific drawings. Engineers and Architects make layout drawings to come up with the desired strengths depending on the rebar detailing that provides diameter, bar designs, portions, size of bars to facilitate the website for steering clear of delays and wastage thus dashing the complete development procedure.

Every single rebar is in depth representing a condition, size, and diameter determined by the requirements in the layout drawing. The Rebar placement will then be revealed in additional element which signifies the concrete address, precise location, and Specific means of placement as needed. The rebar facts and bar bending schedules will demonstrate bar diameter, bar notation, the quantity of bars, bodyweight within the bars, and period of Just about every bar As well as mentioning the general fat for that complete set of bars put within the drawing. In the preparation of rebar information, the stock lengths of bars are trapped in view to make certain there is no wastage Using the substance.

Rebar Detailing and Reinforcement concrete detailing could be modeled and coded in three-dimension Along with the 3D Modelling technologies like BIM Modelling Solutions. The specialized rebar detailing software package like Rebar CAD and AutoCAD utilized for this function might assist each individual member Together with the structural engineering to prepare styles, document, track, and make All round Command.

Getting recognized principle thought of rebar detailing a little of structural BIM modeling, let's make an effort to check out the importance of it in the entire design procedure is. Some With all the reasons are:

Value of Rebar detailing in Structural BIM Modeling

Although second drawings and bending schedules tend to be produced and given, the 3D model is additionally issued to all the team users beginning the consulting engineer and contractor departments as a result of the steel fixers which may be during the ground degree on-website. The combination of this sort of two turn into especially a good selection for web page personnel wherever web site constraints or congestion of reinforcements continue being unidentified till you'll find reinforcement and fixation on web site. For each and every bar, the actual place of repairing is proven in the 3D design coupled with any hindrances or obstructions.

Producing detailing reinforcements in 3D around the 2D course of action is don't just just faster but modeling rebar in the 3-dimensional surroundings allows remove clashes. Although modeling one can visualize if any through the bars tend not to fix in a determined area, thus detect these kinds of clashes inside rebar drawings. There is certainly Probably the facility to assessment the reinforcement in finish element as being a exact depth illustration just before it being staying purchased from the fabricator and sophisticated cages are assembled off-web page.

When There exists a correct rebar detailing solution available, a competent and precise reinforcement model might be designed by importing structural calculations from the structural Assessment method. With Automation concerned the alterations is usually reflected inside the 3D rebar detailing coupled with needed updates to drawings and schedules swiftly when alterations are established somewhere else not like having to perform handbook improvements to 2nd sections waffle pod plastic film Sydney and views.

Instead of dependant on manual enter from paper schedules, the rebar fabricator can extract facts right in the model on the machinery. The concrete pours may very well be nicely-defined within product with other specifics like portions and volumes for making sure more precision in handling substance deliveries. This will permit bigger Command and bring about a lot less wastage and reduction of Total expenses.

Having 3D comprehensive electronic styles will not prohibit the profit that has a single-phase like that during the engineering and detailing stage but may be made use of away from all phases. Obtaining reinforcement totally modeled in 3D, the contractor is assured that it will fit in parts once the time comes it to get mounted on-web site. The information from the product could be used while in the field to allow for contractors to carry out a product-primarily based format by using robotic complete station gadgets together with tracking rebar and resources and pinpointing when and in which are going to needed.

Fixers present on-website will probably be inside the model surroundings to the rebar detailing to precisely comprehend its software, i.e. what's needed where by and when rather than depending on their interpretation of common 2nd drawings.

The structural engineers can easily moreover way more immediately deliver layout reviews, schedules, and drawings throughout the 3D design as in comparison with second designs, thereby boosting style effectiveness. There is additional precision on rate projection dependant on the rebar quantities made throughout the 3D design due to the fact These are far more reputable in comparison with the 2nd drawing take-offs. Not simply this the portions are entirely traceable, allowing for comparisons and checks to get conducted easily.

With these causes, we could conclude that Rebar Detailing a self-discipline of Structural BIM Modelling Companies is a person While using the very important standards to the All round accomplishment within the challenge lifetime cycle. To summarize, getting Rebar Detailing the rebar contractor can center on producing rebars there won't be any should really estimate reinforcement necessities for procurements at the internet site on account of productive 3D products. The design will depict the requirement for anchors and laps within the drawings thus making sure design adequacy In combination with lowering wastage. The general waste and time delays are lowered at the Online page since every one of the shape drawings tend to be offered. Based on these facts the bars could be simply fabricated based on the styles and amount of bars required.

Kel Mitchell Then & Now!

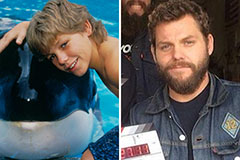

Kel Mitchell Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!